Learn how 3D modeling solves complex façade challenges by improving accuracy, coordination, and reducing costly design errors.

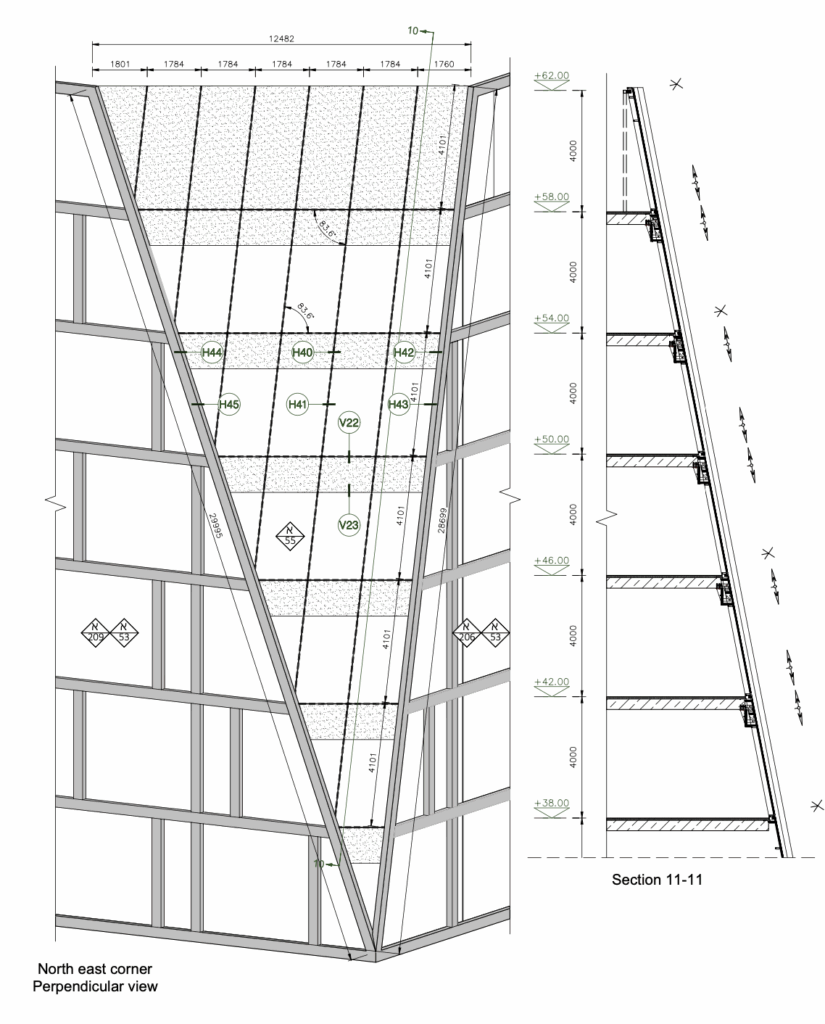

Modern facade systems are becoming more complex every day. As building designs grow more creative, traditional 2D drawings often fall short—especially in complex junctions, corners, curved surfaces, or custom connections. That’s where 3D modeling becomes essential. For example, in double-curved facades, modeling avoids fitting errors.

What Is 3D Modeling in Facade Engineering?

3D modeling is the process of creating a digital, three-dimensional representation of façade components. These models go beyond simple geometry—they include layers of detail such as:

- Material thicknesses

- Joinery methods

- Fastening systems

- Interaction with structure and MEP systems

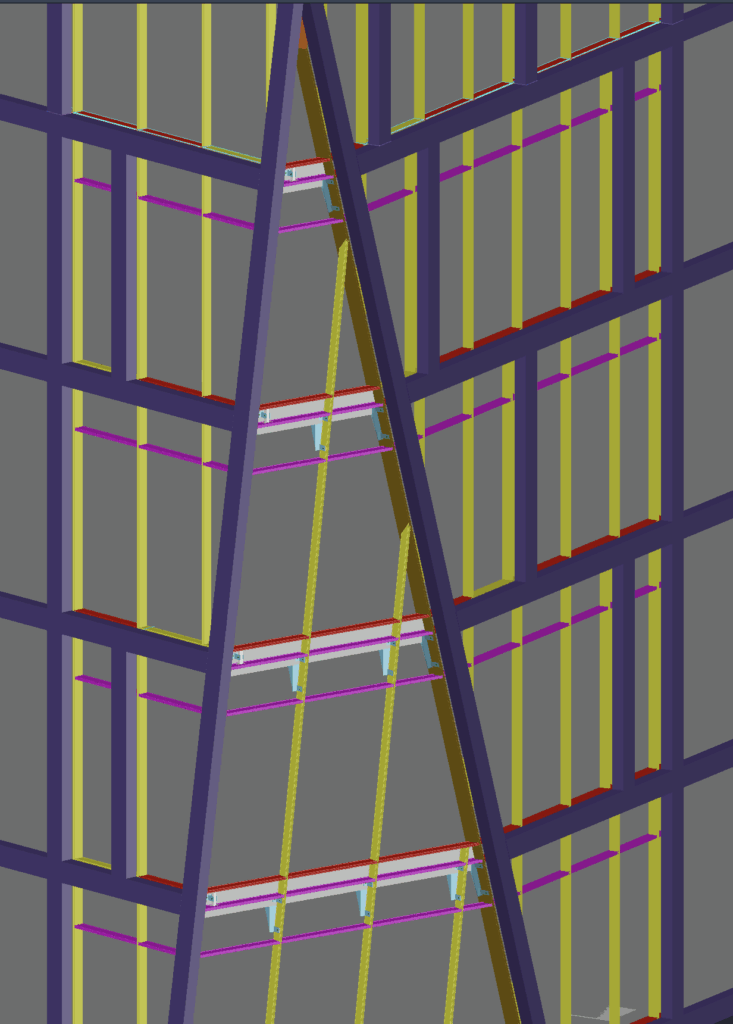

Tools like Revit, Rhino, or SolidWorks allow facade engineers to visualize and analyze complex points before fabrication begins. Therefore, teams can avoid costly rework.

Why 3D Modeling Is Critical for Complex Facade Areas

1. Clear Understanding of Difficult Geometry

When working with double-curved panels, cantilevered fins, or irregular openings, a 3D model helps everyone involved understand how elements connect in space.

2. Fewer Errors During Fabrication

3D models expose hidden clashes between façade elements, structure, or services. Fixing these early avoids rework and costly on-site modifications.

3. Better Coordination with Stakeholders

A 3D model makes it easier to share ideas with architects, structural engineers, and contractors. Everyone sees the same thing, reducing misunderstandings.

4. Faster Decision-Making

With 3D visualization, design options are easier to evaluate. As a result, This speeds up approvals from consultants and clients.

When Should You Use 3D Models in a Facade Project?

You don’t need 3D modeling for every detail. However, it is strongly recommended for:

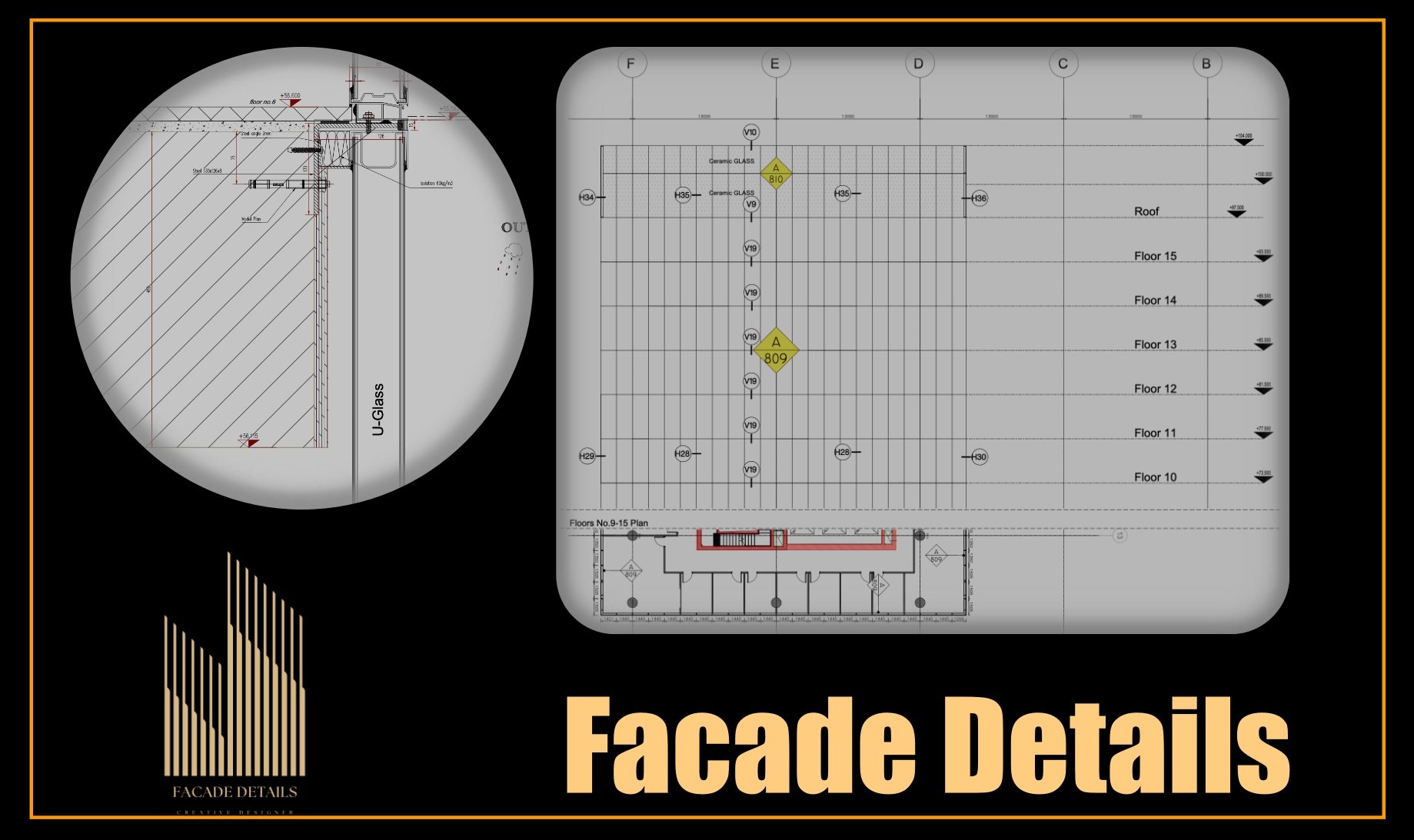

- Corner joints with multiple materials

- Canopies, fins, and projecting frames

- Connections to structure (especially hidden anchors)

- Unitized panel junctions

- Areas where glass, metal, and waterproofing overlap

Using 3D early in the design or shop drawing phase helps avoid surprises later.

Real-World Example

At FacadeDetails.net, we use 3D modeling in many of our shop drawing packages. For instance, in one recent metro station project, a complex aluminum-to-glass connection required custom brackets and waterproofing. A 3D model allowed our team and the contractor to coordinate and install it with zero on-site conflict. In addition, it speeds up client approvals.

Final Thoughts

In today’s fast-paced façade industry, 3D modeling is no longer optional for complex zones—it’s a powerful tool for accuracy, coordination, and project success. Whether you’re working on a high-rise tower or a public infrastructure project, integrating 3D modeling into your workflow will pay off.

👉 Need help with 3D modeling or advanced shop drawings? Contact our team to get started.

Leave a Reply